Z TOP sensor now available as standard equipment

TOP Sensor – the new standard for accurate and safe height measurement on COMAGRAV machines

We have been working for a long time to make our CNC machines faster, more accurate and safer. One of the most important innovations this year is therefore the TOP Sensor – a new sensor for automatic measurement of material and underlay height, which we now supply as standard on all NOTUS and DIGI CORSA machines.

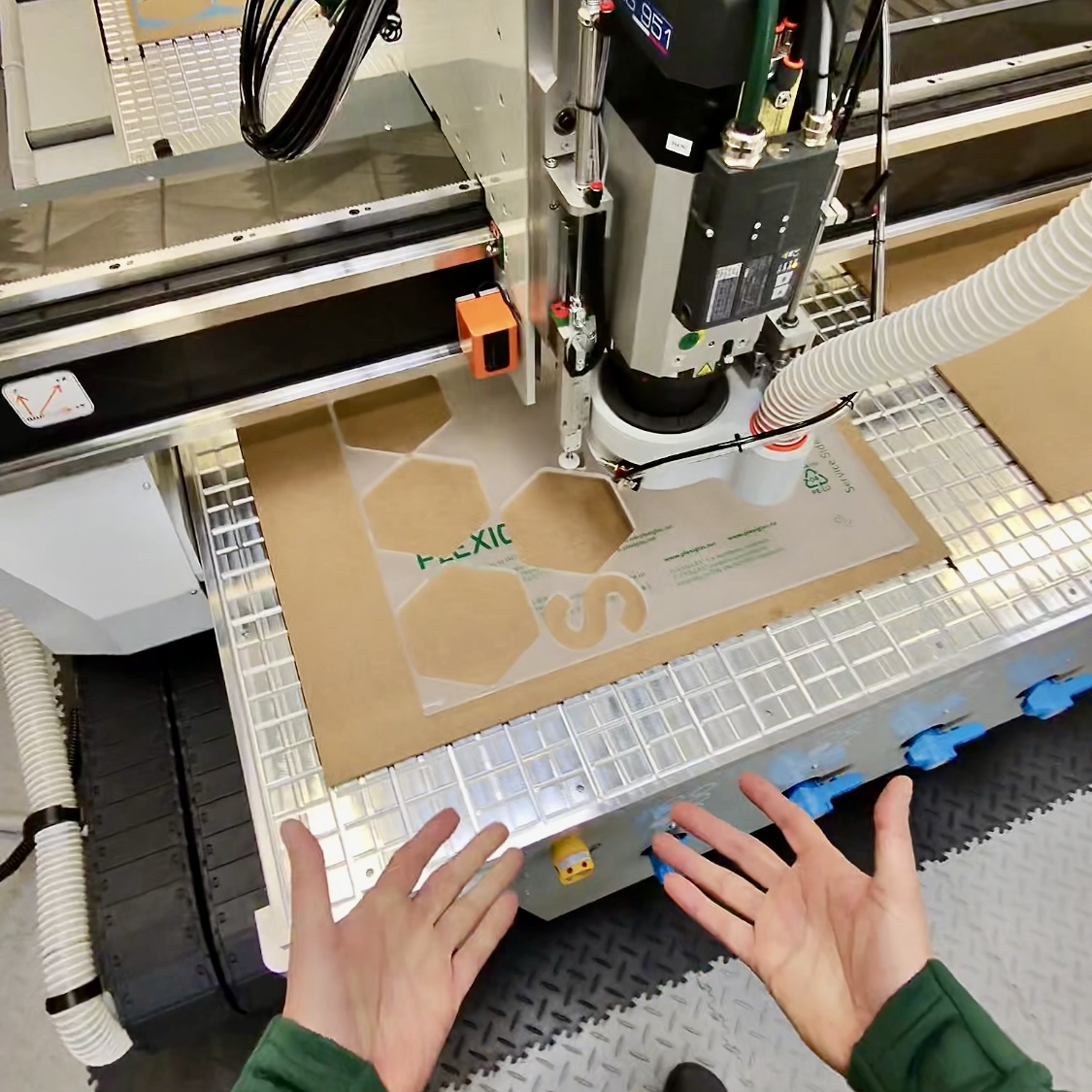

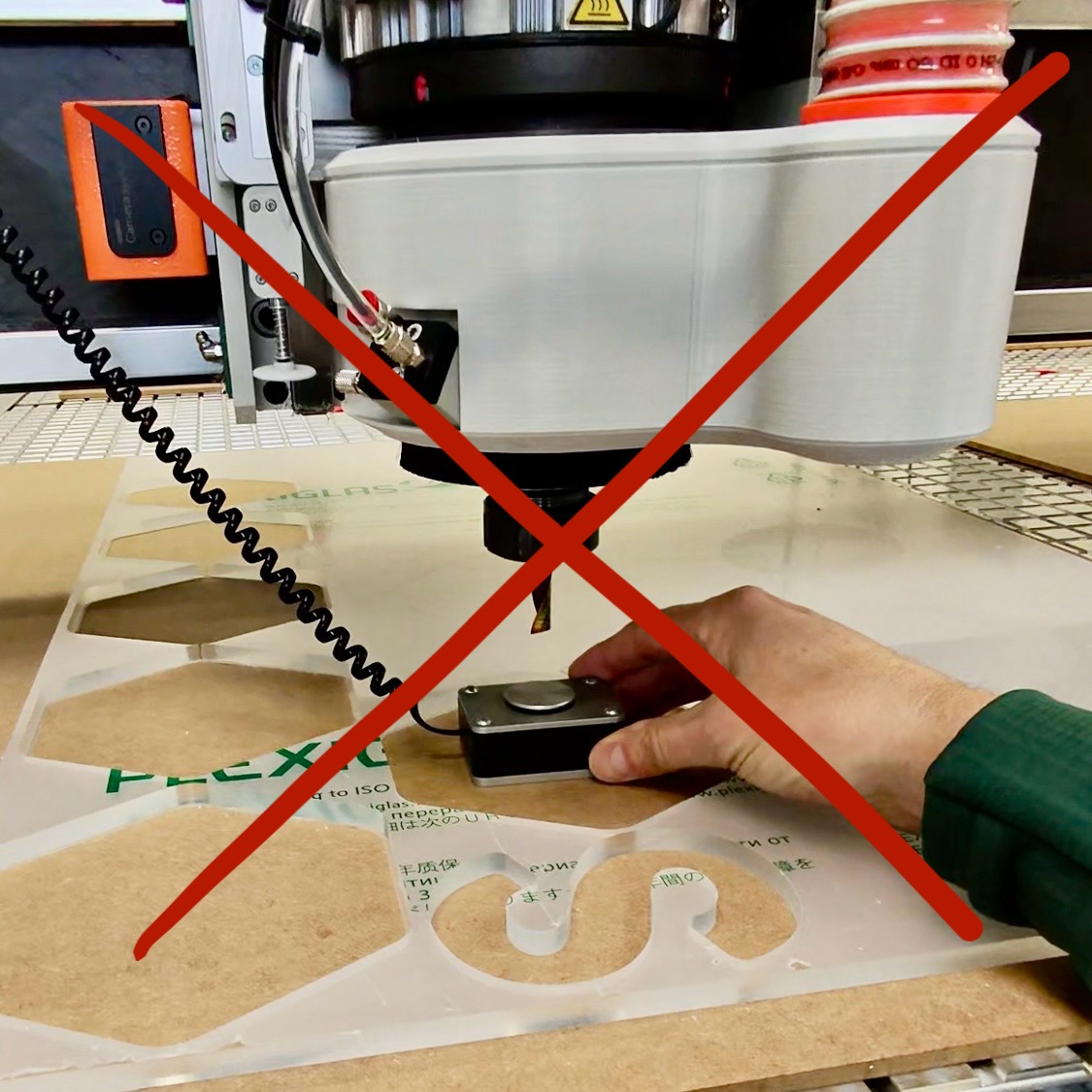

TOP Sensor fundamentally changes the way the operator calibrates the tool height. No more manually placing the “mushroom” under the sharp tool, no more risk of error or damage. Instead comes a fully automatic, fast and maximally safe solution.

Why we have created the TOP Sensor

The original measurement using a metal “mushroom” worked for years – but required careful handling and in certain situations posed a risk to the tool, material and machine.

Especially with high tool change frequencies or less experienced operators, manual measurement could cause production delays.

TOP Sensor simplifies and automates this process. The operator does not have to do anything at all – the machine measures the height itself, instantly and with high accuracy.

How TOP Sensor works

The TOP Sensor is located directly in the working area of the machine and is used to:

- measuring the height of the underlay,

- measuring the height of the material,

- detecting the exact position from which the tool should start working.

The measurement is completely automatic and without any manual manipulation of external elements. The operator thus eliminates errors while increasing operational safety.

Camera independent – but even better with a camera

TOP Sensor does not require any additional accessories. However, if the machine is equipped with a camera, your work becomes even more convenient:

- The operator selects the exact location on the screen where he wants to take the measurement,

- the camera shows a detailed view of the selected area,

- the operator simply clicks to confirm the measurement point.

This is a simple but significantly clearer way of working, especially when measuring small parts or complicated shapes.

Measuring tool lengths directly in the tool magazine

On machines equipped with automatic tool changing, the TOP Sensor is complemented by another dedicated sensor located directly in the tool magazine.

This sensor provides:

- Automatic tool length measurement,

- precise alignment at each tool change,

- tool inspection without the need for operator intervention.

This increases machining precision while reducing the time required to change and check milling tools.

Safety thanks to artificial intelligence in the PILOT system

Modern CNC machines need advanced protection methods.

That’s why AI tool tray presence checking is also integrated into the PILOT system.

Machine learning evaluates whether a position in the magazine is actually occupied by a tool.

Thanks to this:

- no spindle collisions during tool change,

- the machine immediately detects a missing or misplaced tool,

- spindle and machine life is significantly increased.

Safety and reliability are essential for us – and this is where automatic detection brings a huge advantage.

TOP Sensor as the new standard

From now on, TOP Sensor is part of the standard equipment of all NOTUS and DIGI CORSA machines.

With this step, we are bringing our customers a more modern, more convenient and safer way of working that:

- speeds up production preparation,

- reduce errors,

- increase operator safety,

- protect tools and spindles.

If you would like to try TOP Sensor in practice, we will be happy to show it to you in our showroom in Poříčí nad Sázavou.