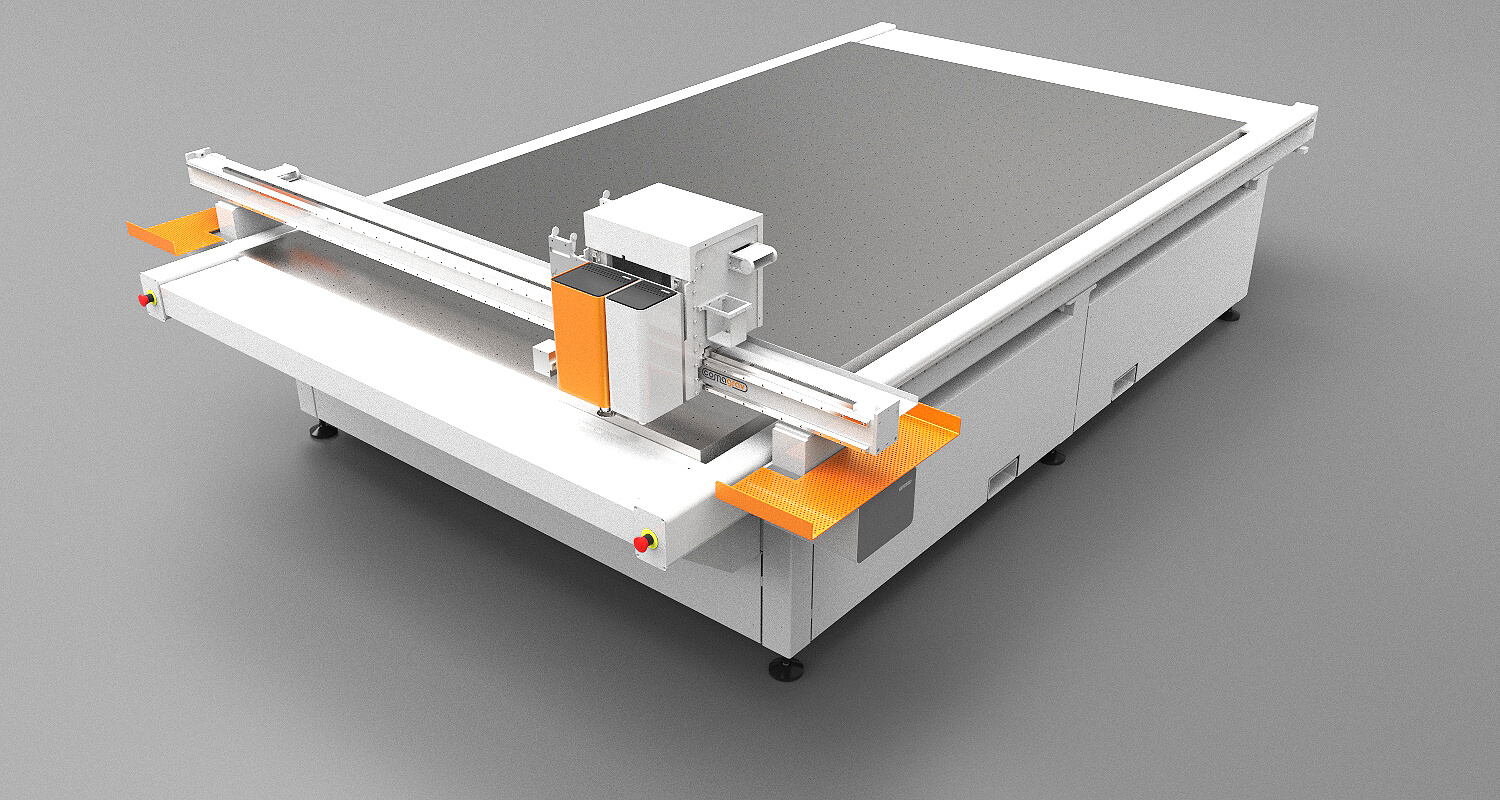

We supply COMAGRAV CNC machines with a complete software solution.

Everything from 2D and 3D engraving software to packaging design and POS software. We offer solutions for wood processing, materials in rolls, leather, fabrics, plastics production, engraving, vacuum forming and much more.

Track preparation programs for milling and cutting Vectric

Programs for RIP, print preparation and graphics cutting SAi Flexi

Programs for creating packaging, POS/POP stands SAi Flexi Display&Box

Programs for creating packaging, POS/POP stands AG/CAD Kasemake

COMAGRAV supports popular RIP softwares for digital printing, preparing data for cutting is a matter of moments.

COMAGRAV TDP PILOT control software

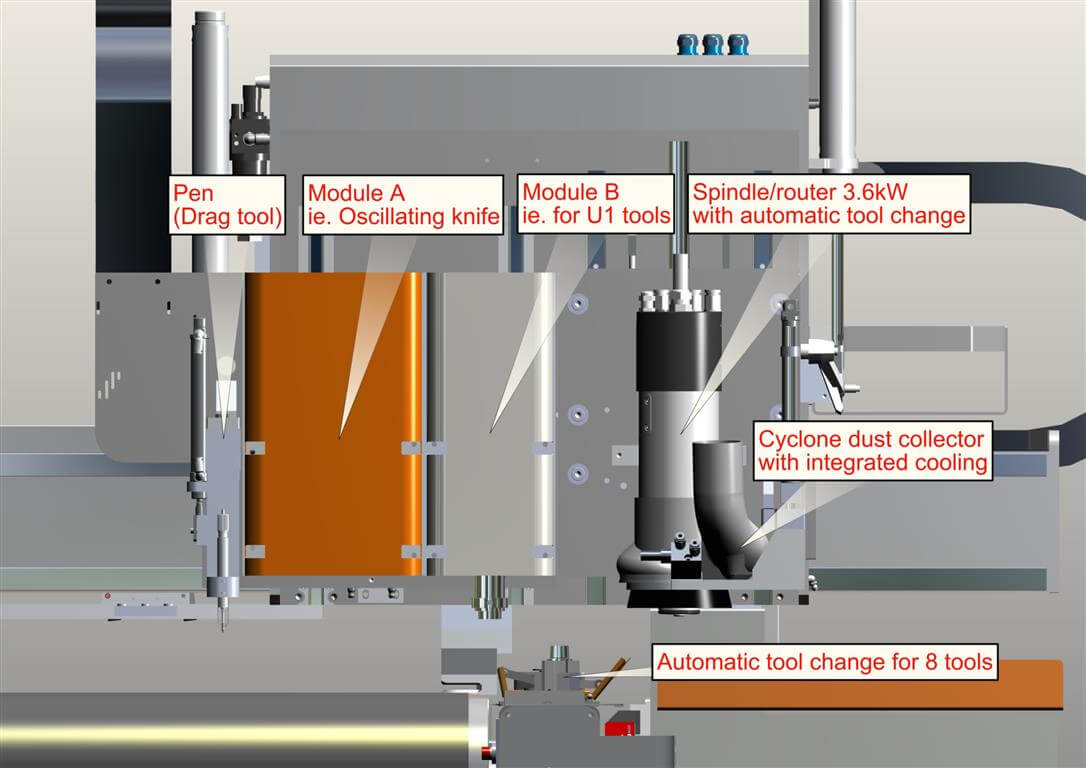

The COMAGRAV machine control system has been given a new core, giving the machines additional scalability. Now we can fit the machines with any number of modules. No additional programs are needed if you use multiple modules.

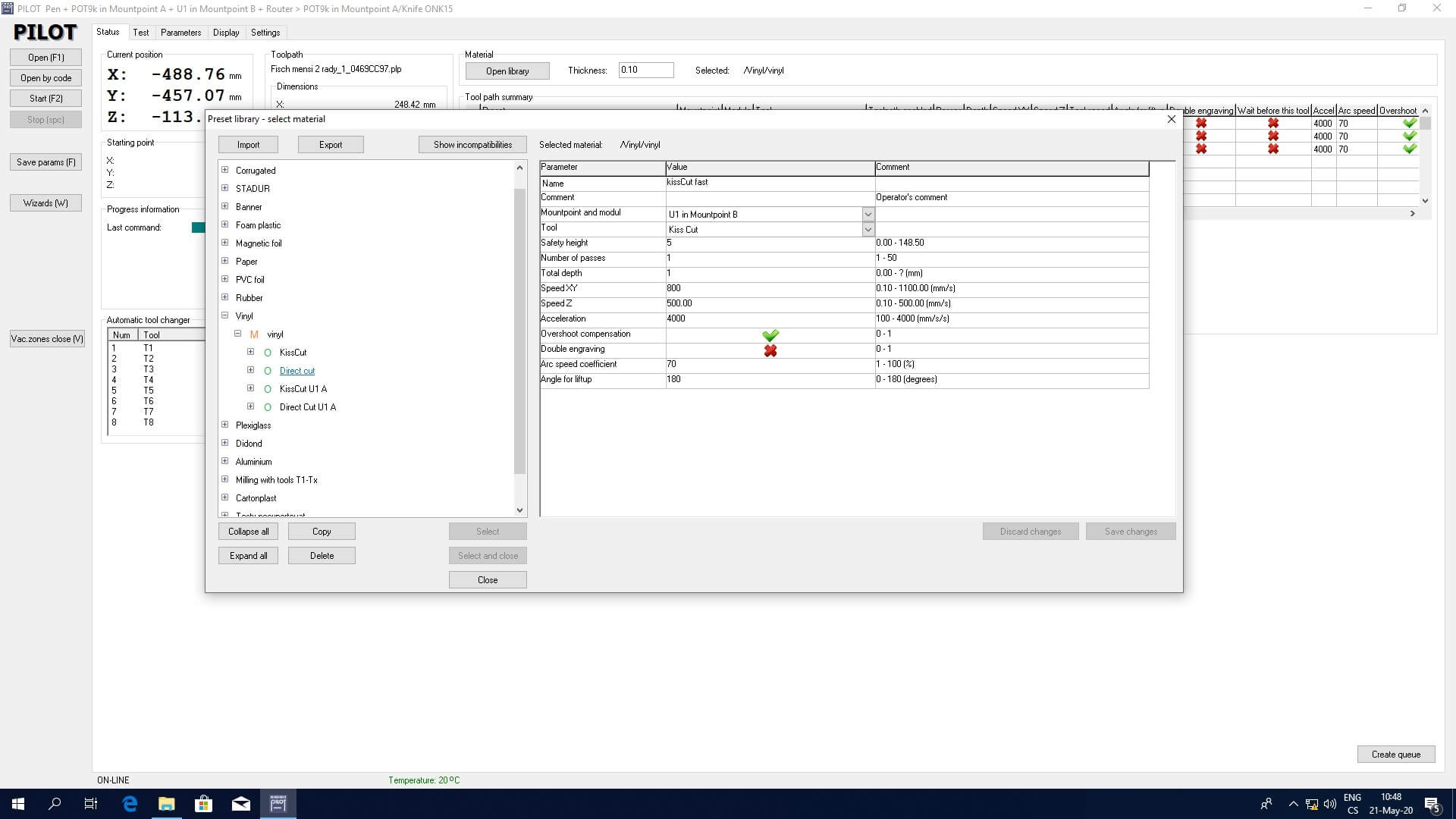

PILOT TDP contains a library of materials and tools, the operator simply selects a tool from the library for his material and starts the cutting process.

This innovation reduces the demands on the qualification of the operator and speeds up cutting operations.

As part of the delivery of the new machine, complete installation is FREE, including training in control software and acquaintance with the machine. We provide training personally or online via TeamViewer.

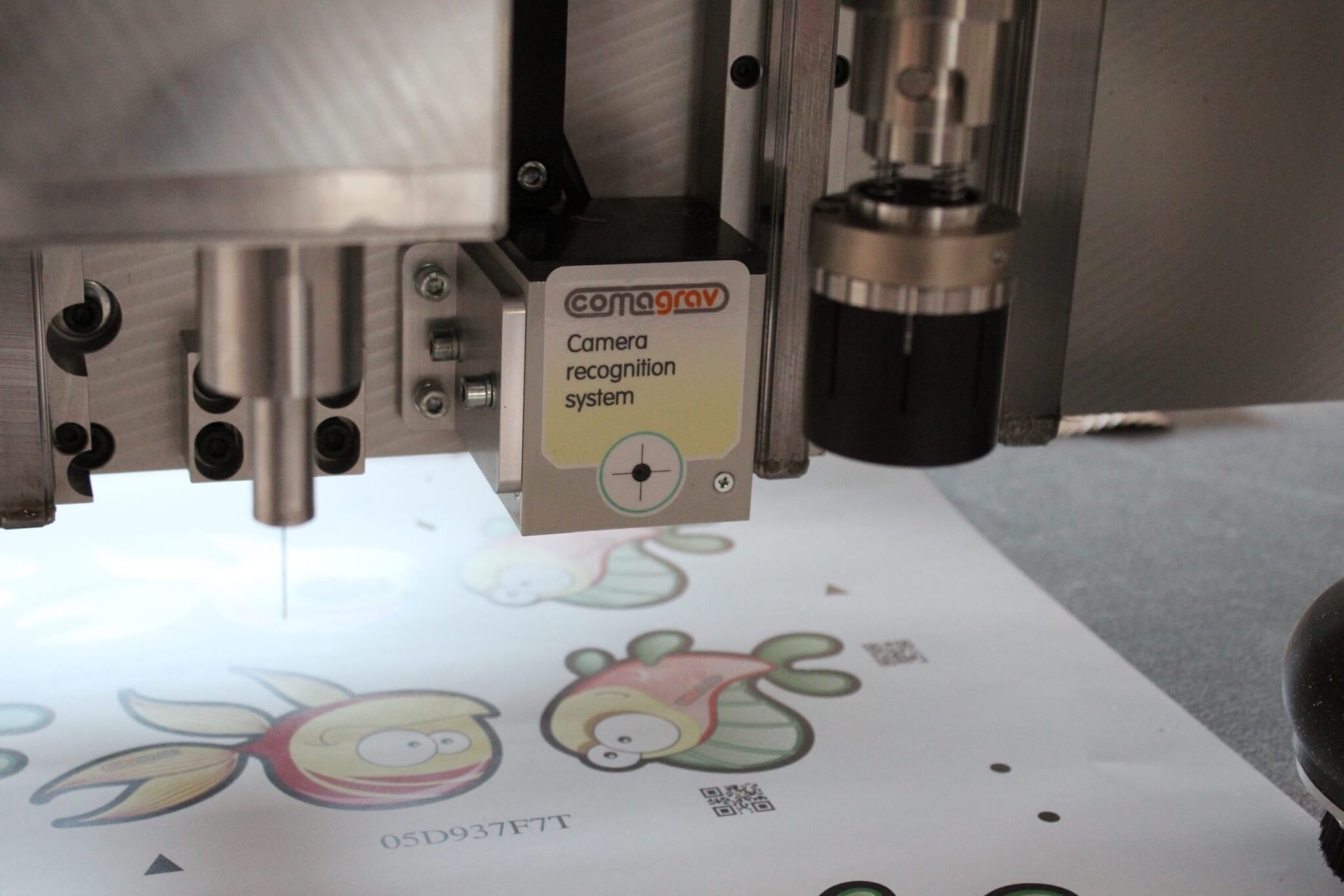

Integrated automatic camera system

The large field of view of the camera system enables fast automatic search for print reference marks, QR code, both on board materials and textile materials. QR code uploads all data to the system and after automatic reading of the code by the camera, the machine cuts itself according to the entered values. This is an automation where the operator does not have to be present at the machine to load file after file. Together with the automatic material unwinder and the table feed, this means almost endless cutting without the need for operator assistance.

The only COMAGRAV TDP PILOT software for everything

The coordinate system relative to the table corner – position x-0 and y-0 is at the table corner – a clear starting point, the operator knows where to load the material. Thanks to this, the camera system and the QR code reader automatically searches for and reads the required QR code, where all the information needed for automatic material cutting is stored. No machine operation is required.