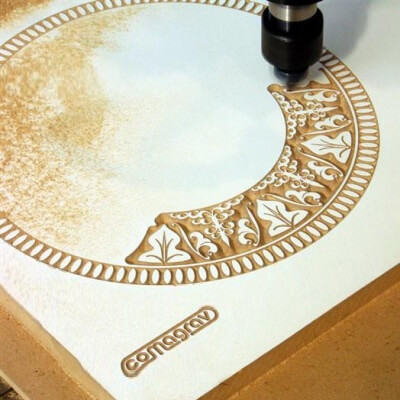

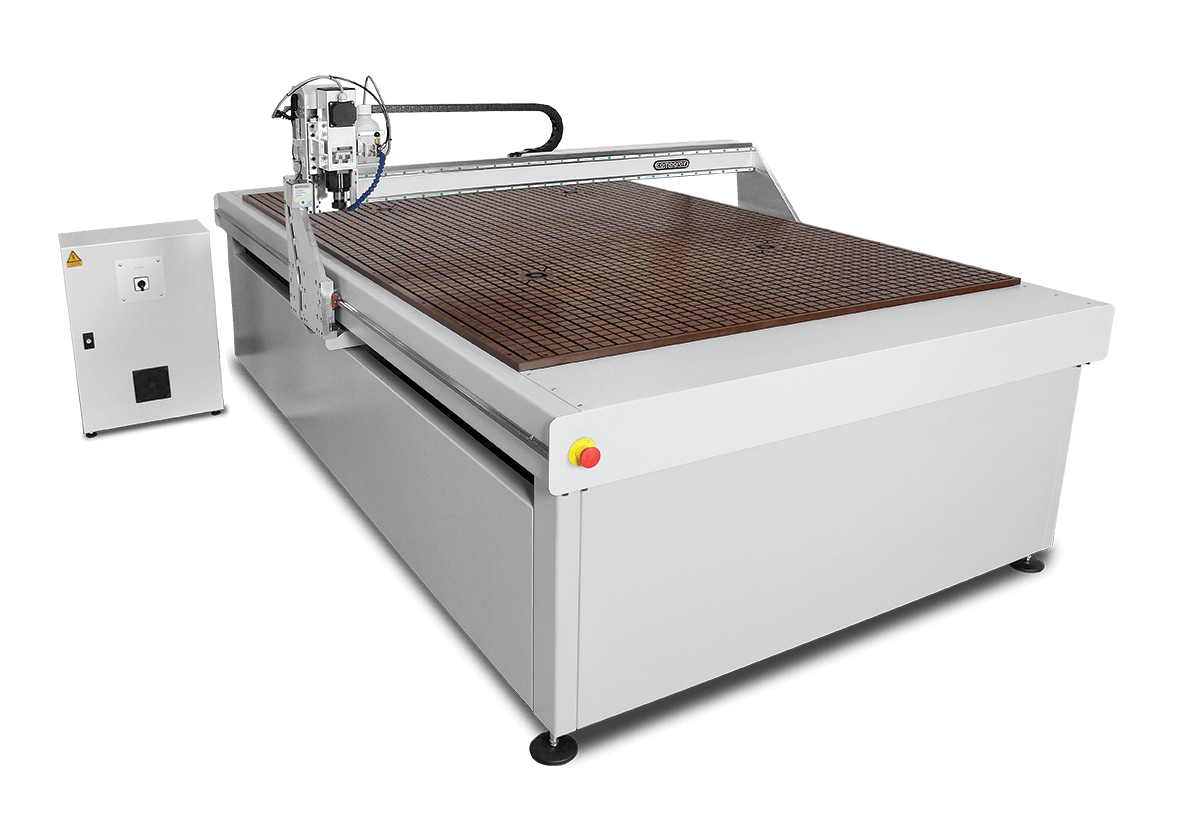

COMAGRAV ECO represents great value for money

COMAGRAV ECO is our basic CNC router for cutting and milling operations.

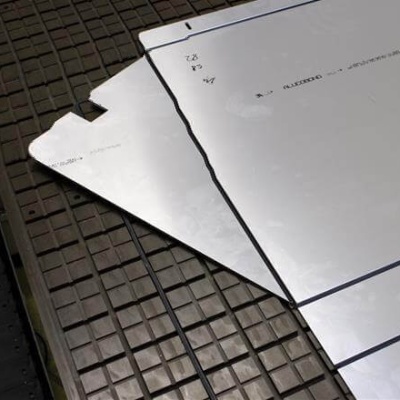

It is ideal for cutting plastic, aluminium, PMMA, wood, composite panels, MDF, plywood and similar materials.

COMAGRAV ECO is CNC router great for

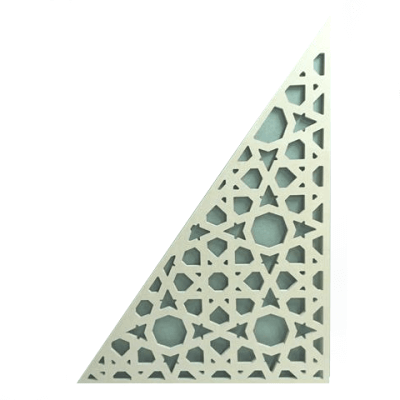

• plastic fabrication

• signage

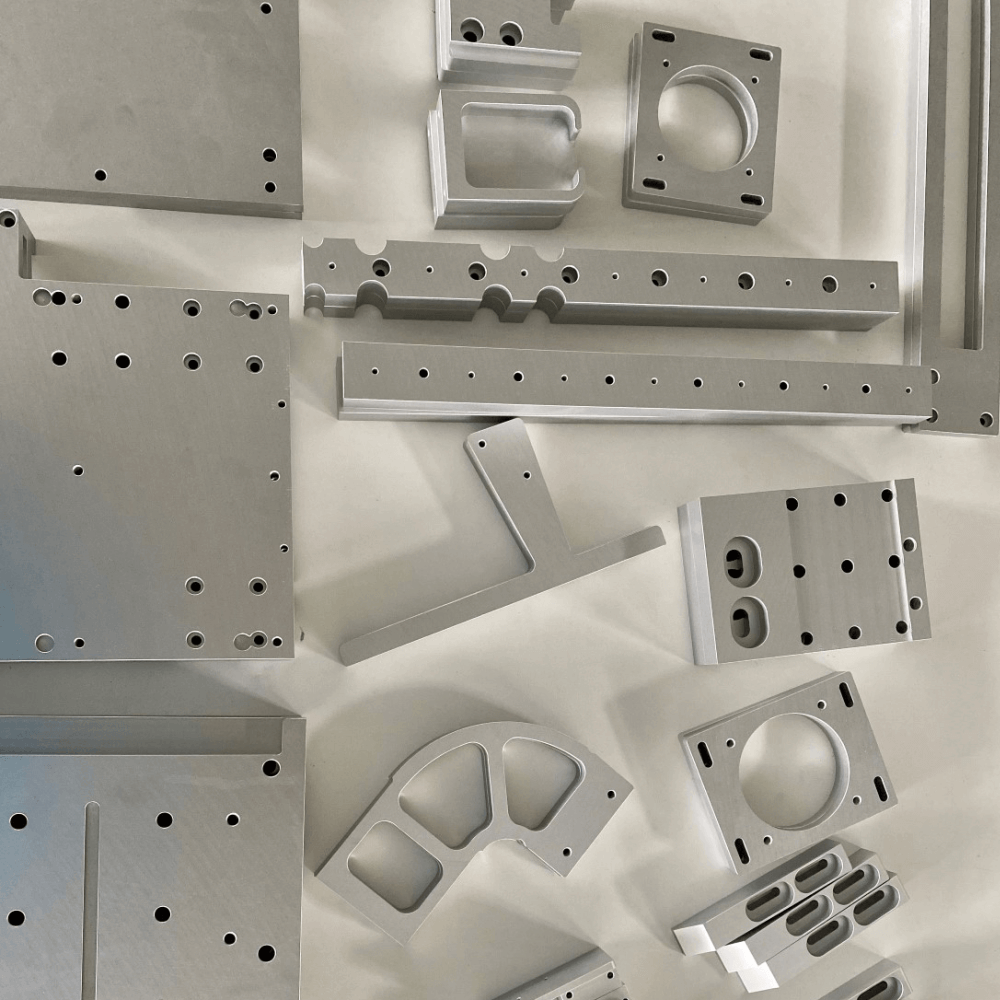

• aluminium processing

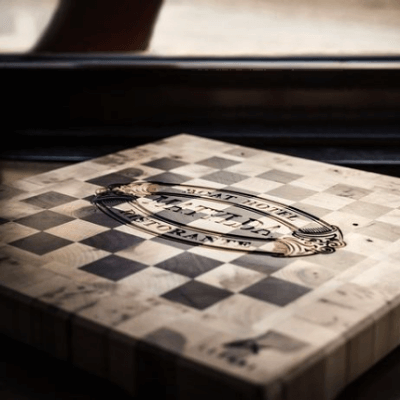

• woodworking

• composites

Mechanical design

Design of the machine is characterized by prefabricated steel with crossbars. The structure is very clever – less vibrations and more material saving – thus environmental and economical friendly.

COMAGRAV ECO is driven by stepping motors (in microstep mode) in all axes. Racks and pinions are installed for correct motion control. Accuracy is ensured with smooth axial movement with planetary gearboxes in X and Y axis – which is not so usual in this price range.

You can choose from two worktable solutions

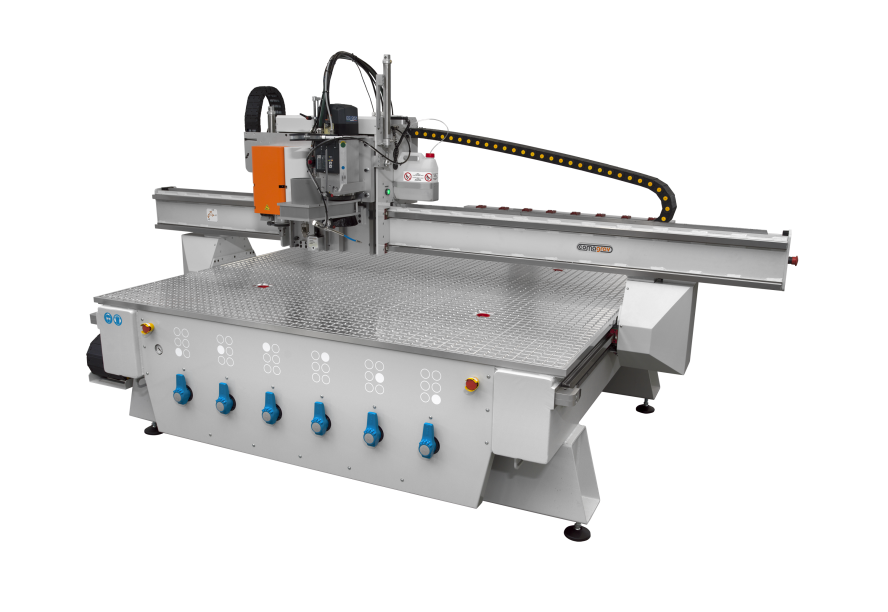

T-slot aluminium worktable for manual fixing

The worktable is made of precise aluminium profiles and allows clamping in T-slots.

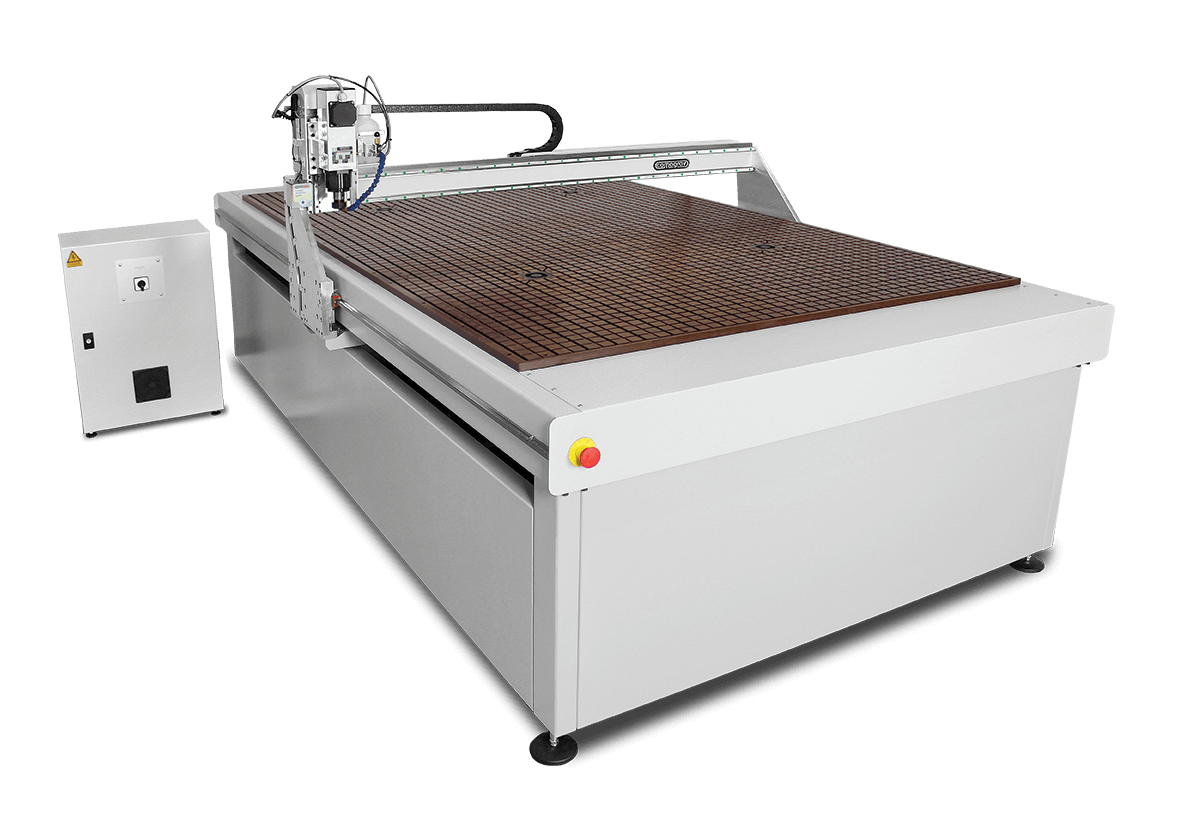

High pressure vacuum worktable for automatic fixing

Solid worktable made of phenolic resin together with powerful Becker pump (2.4 kW) is perfect and well-proven solution.

The machine is equipped with safety elements for emergency stop of the machine.

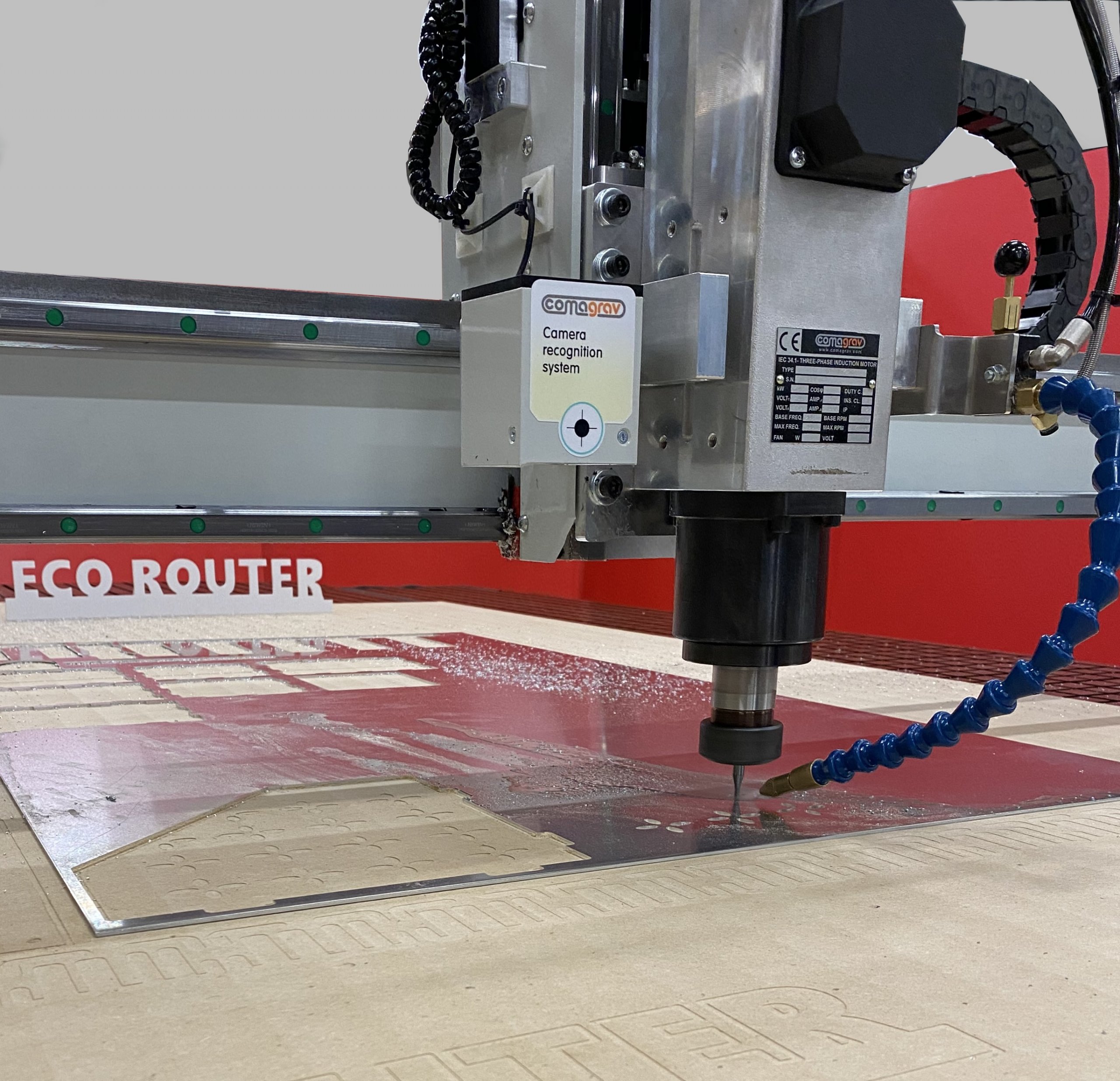

CNC router is equipped with the professional spindle for milling.

Its 2 kW power is well balanced with machine design and power of vacuum. Maximum speed is 24.000 RPM. Thanks to double ceramic bearings, hardened shaft, balanced and forced cooling, the spindle can run at maximum speed throughout the full shift.

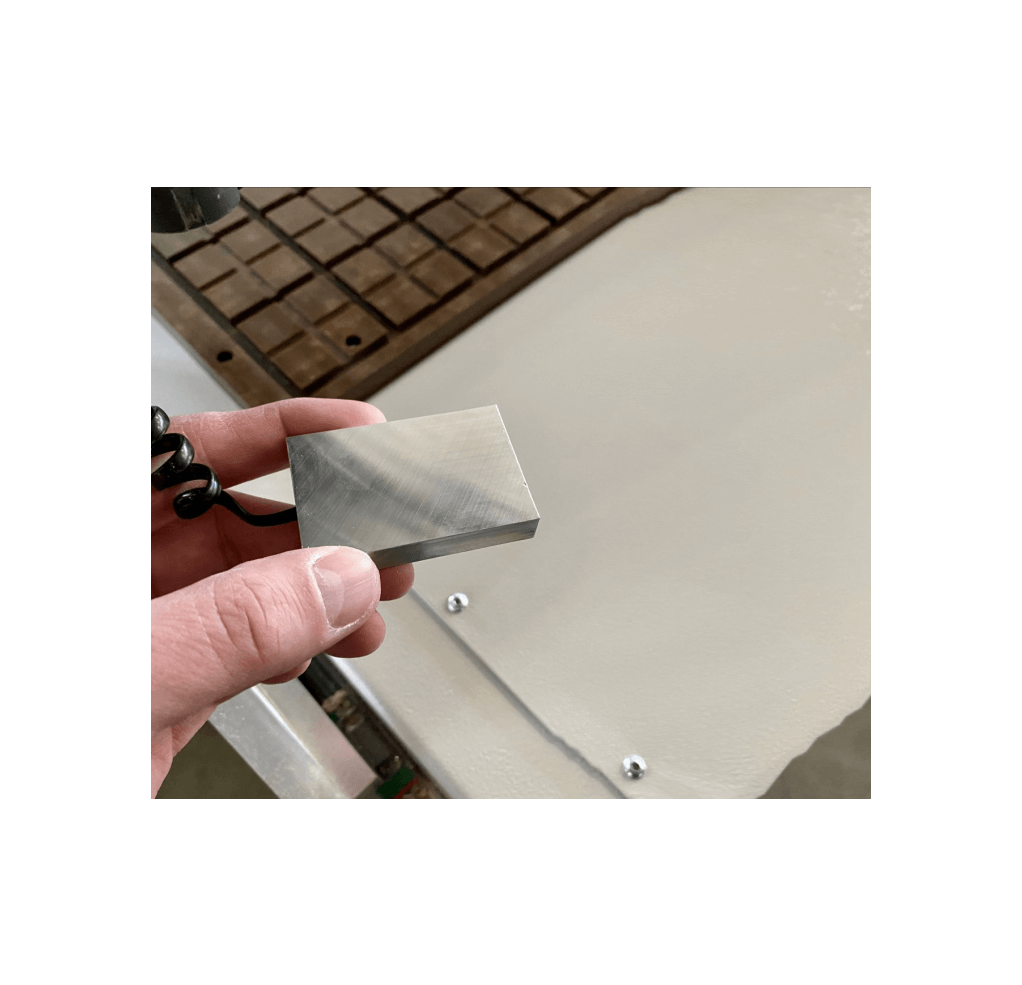

Automatic Z sensor for measuring of tool length is standard for COMAGRAV ECO.

Material processed by COMAGRAV ECO

Technical specifications

Parameters

| Working area | 1500x2500 mm |

| Frame | Prefabricated steel structure with crossbars |

| Working table | Vacuum with high pressure pump (2.4 kW Becker with footswitch) or T-slots for fixture with clamps |

| Drivers | Stepping motors (microstep) in all axes, rack and pinion + planetary gears for XY, ballscrew for the Z axis |

| Spindle power | Professional electrospindle with an output of 2 kW |

| Maximum spindle speed | 24.000 RPM |

| Maximum speed | 100 mm/s |

| Maximum material height | 110 mm |

| Resolution | 0,0068720 mm |

| Weight | 400 kg T-slot, 540 kg Vacuum table |

| Collets | 6 mm collet (ER20), wrenches for tightening |

| Z sensor | Z sensor for tool automatic tool lenght measuring |

| Control software | PILOT |

| Tool change | Manual |

| Camera system | Compatible with RIPs (option) |

| Control PC | DELL Corei3 (option) |

| Vacuum pump | Becker 2.4 kW high pressure (option) |

| OS | Windows 7/8/10 |

Options

| Control panel with DELL PC and Windows 10 IoT Enterprise | |

| Camera system | |

| Dust collector | |

| Spray cooling system for aluminium cutting | |

| Vacuum pump Becker 2.4 kW high pressure |