Composites and polymeric materials processing

Sports and automotive industry

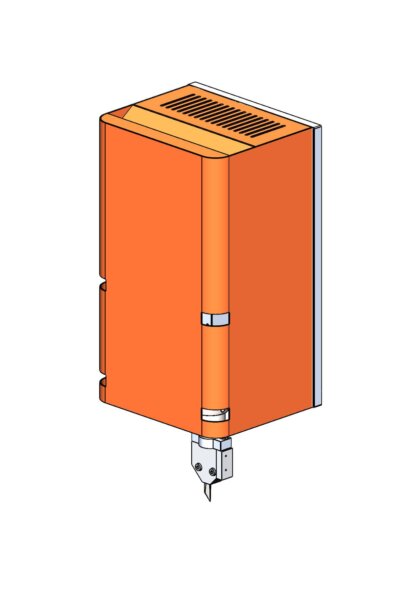

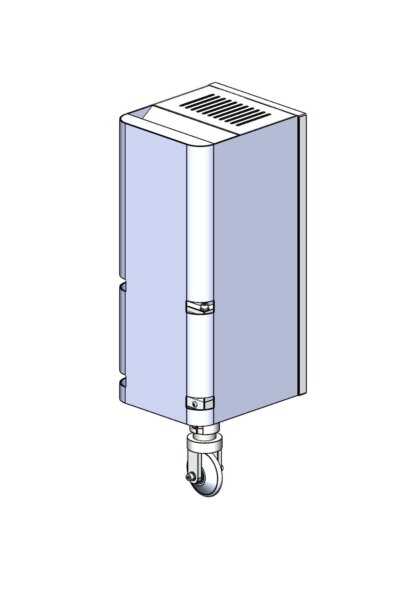

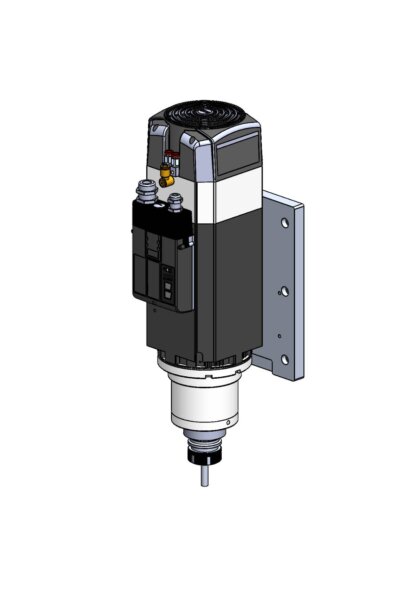

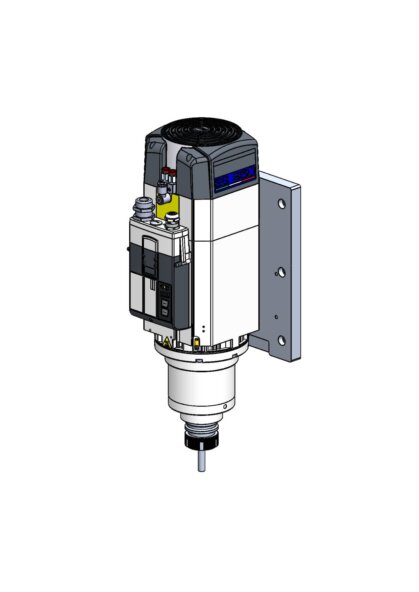

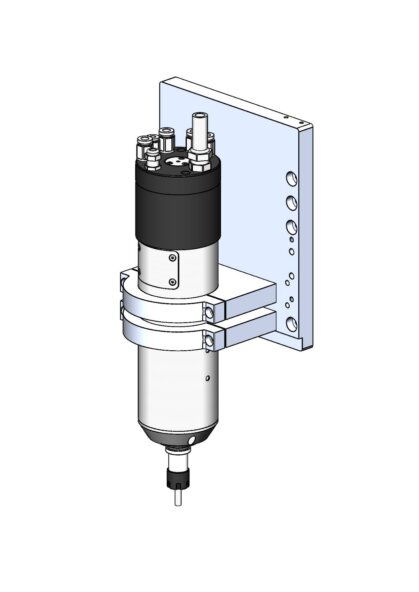

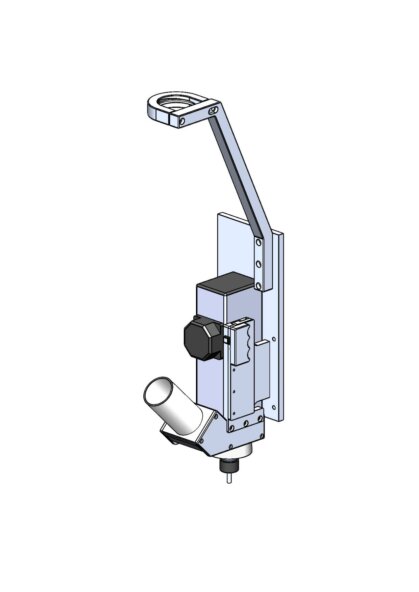

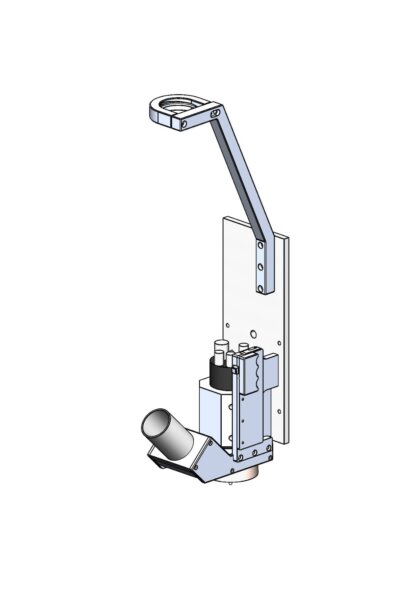

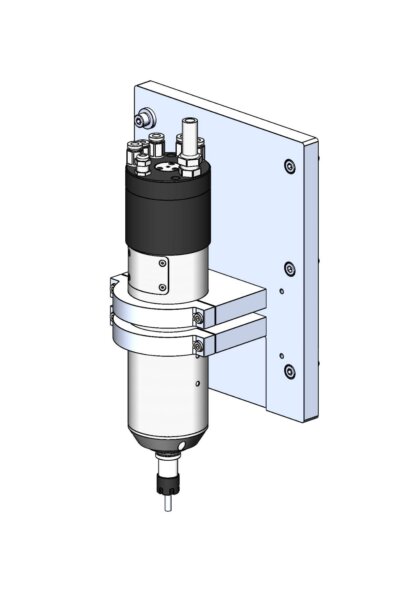

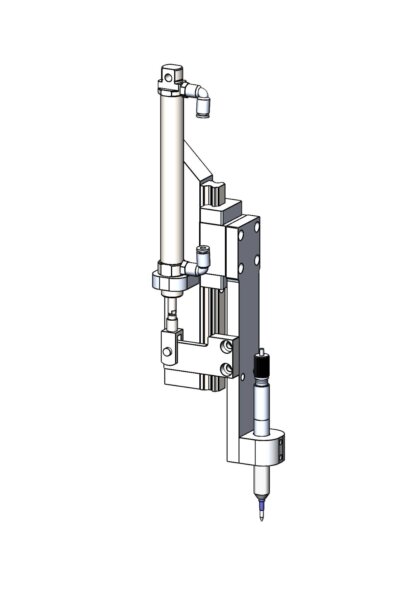

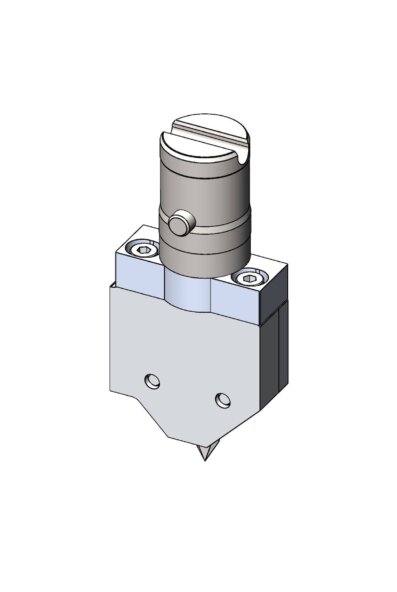

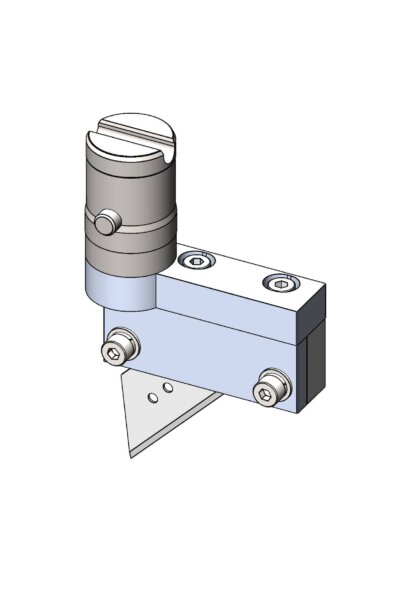

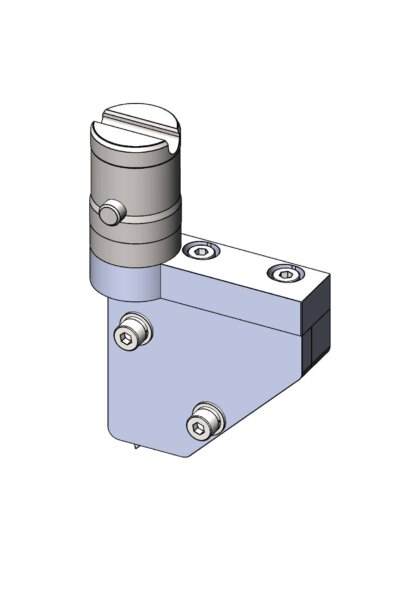

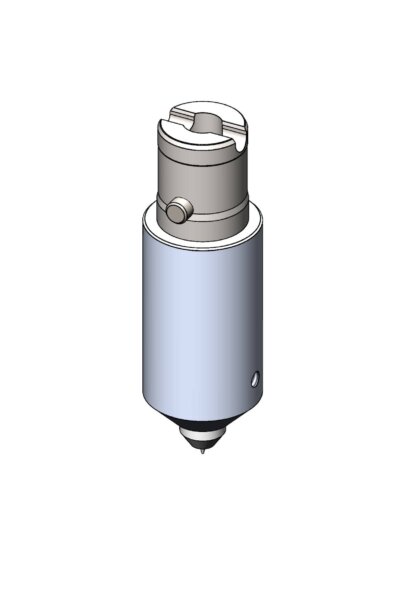

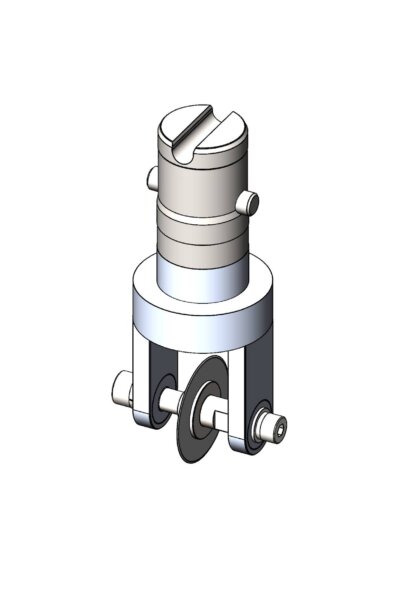

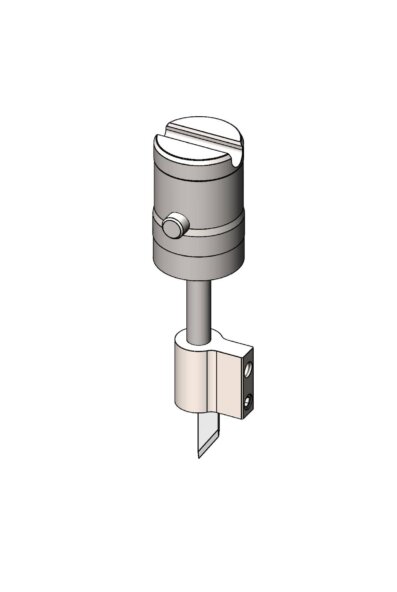

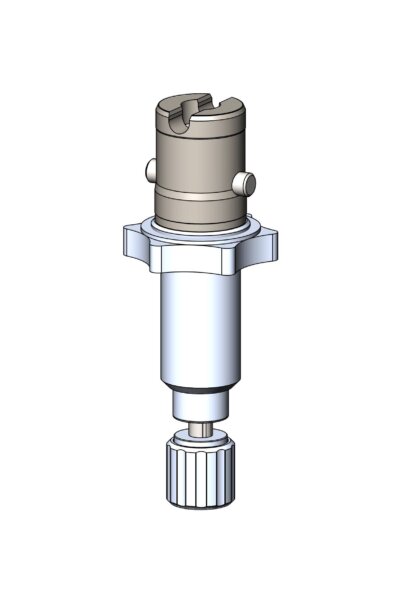

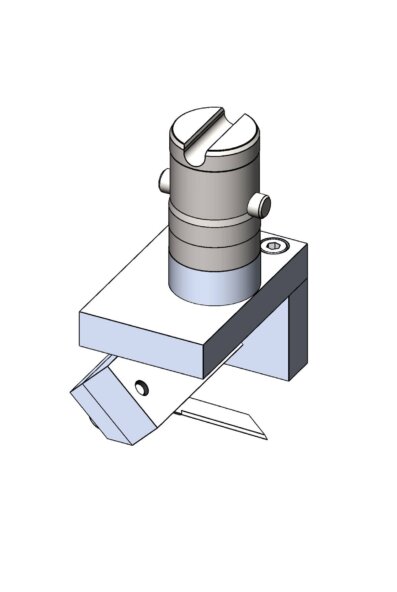

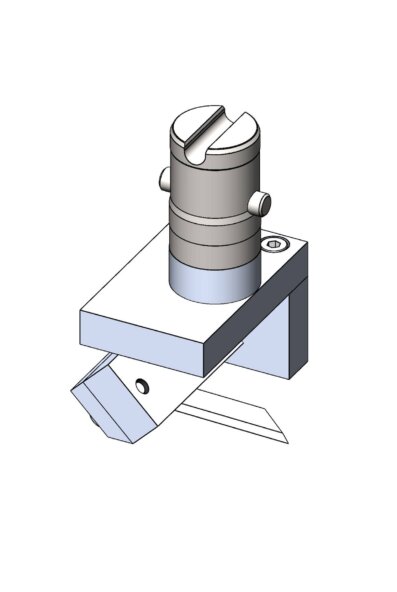

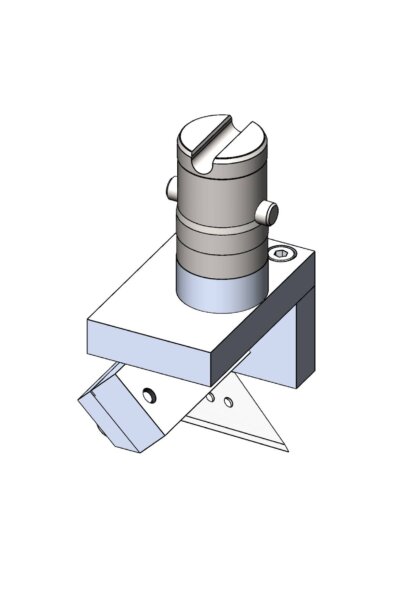

Composites and polymeric materials. In an effort to reduce power consumption and increase performance, acceleration, stiffness and vibration damping are always the topics and composites are often the answer. COMAGRAV has extensive experience in processing a wide range of carbon fibers, composites, polymeric materials and providing cutting solutions that meet this challange.

Industrial applications

Do you operate highly integrated production lines for carbon fiber processing? Do you face the challange of producing light products economically, in large quantities and for customers with the highest quality requirements?

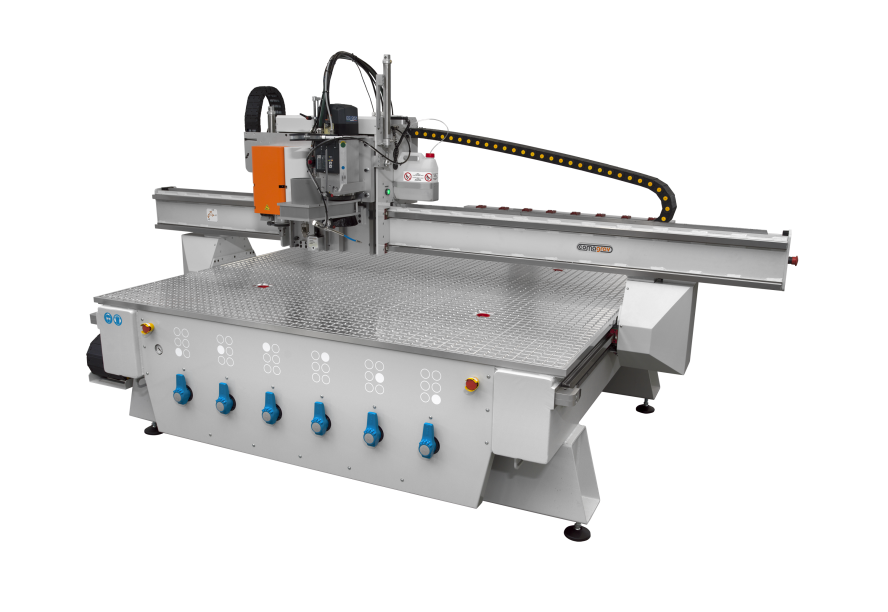

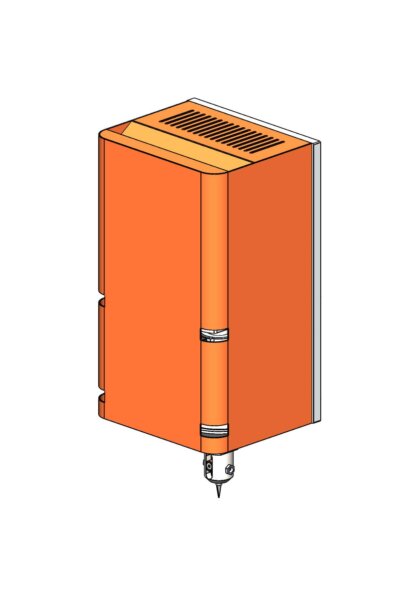

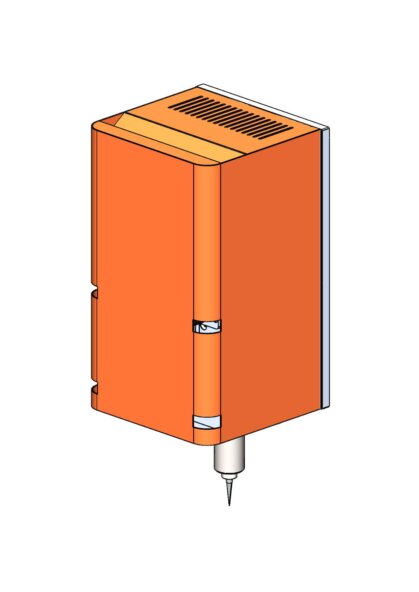

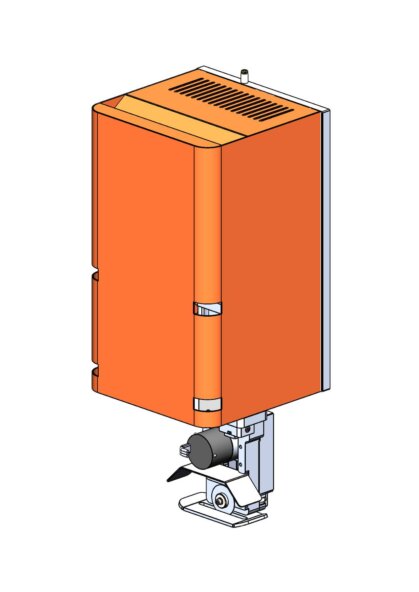

We offer modular, flexible and easily upgradeable machines for efficient and economical cutting of various materials.

Wind energy

Glass fiber reinforced composites and polymeric materials have become indispensable in the construction of wind farms. Many manufacturers of composite parts for rotor blades, tower and other components have chosen the COMAGRAV multifunction cutting device.

Air transport

Lightweight and high-strenght materials have become indispensable in all aspects of transport. For example in passenger planes, more and more composite materials are being used in interiors. They offer manufacturers significant weight reduction.

Composites and polymeric materials

Advantages of composite materials usually lie primarily in their weight. Compared to additional steel components, even with a larger volume, they still have a significantly lower weight, which facilitates their transport and quick and easy assembly and disassembly. Composite materials do not deform significantly (their elastic limit corresponds to the strenght of). They have a very high fatigue limit and are stable and reliable. Composite materials have excellent fire resistance compared to light alloys, however, vapors can be toxic. A disadvantage of composite materials with an epoxy matrix may be the sensitivity to diluents. Other common chemicals used in machines such as oils, greases, solvents, paints or petroleum do not damage the composition. Composites ages depending on humidity and temperature.

Three-component composites are also produced, which form the carrier component (fibers, staple, fabric, thermoplastic foil), binder (thermosetting and thermoplastic resins, rubbers) and filler (inorganic – mica, quartz, glass; organic – wood flour).

Absorbency of composites may be undesirable. In addition to excellent mechanical and strength characteristics, composite materials have absolute corrosion resistance even in aggressive environments, including UV radiation, and excellent thermal insulation properties. Composite materials are colorfast and laminate constructions are tested for long-term operation. Variability of shapes and colors without restrictions allows a perfect adaptation to the specifics of the building structure.